Do you know the material of mini warehouse

Do you know the material of mini warehouse?

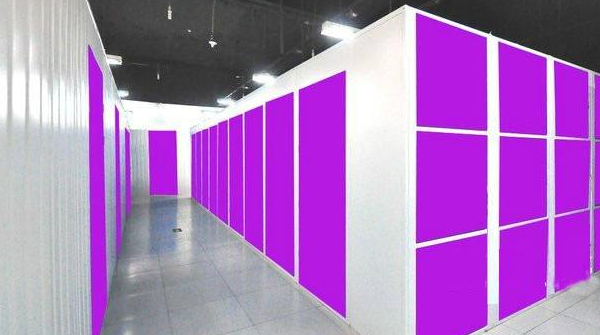

Most people only know about the mini warehouse, but they don't know what it is made of. Below, I'd like to introduce the material of mini warehouse - sheet metal.

Sheet metal is sometimes referred to as pulling metal. Generally, some metal sheets are pressed by hand or die to produce plastic deformation to form the desired style and size. Furthermore, they can be further welded or machined to form more disordered parts. For example, the common chimney, sheet metal furnace and car shell are sheet metal parts.

Sheet metal processing is called sheet metal processing. For example, using plates to manufacture chimneys, iron drums, oil tanks, ventilation pipes, elbow big and small ends, round place, funnel shape, etc., the main processes are cutting, bending and trimming, zigzag forming, welding and riveting

Wait.

Sheet metal parts are sheet metal parts, which can be processed by stamping, zigzag, drawing and other methods. Generally speaking, they are parts with the same thickness in the processing process. The corresponding parts are cast iron parts, casting parts, and mechanical manufacturing parts. For example, the iron shell outside the car is sheet metal parts, and some kitchen furniture made of stainless steel is also sheet metal parts.

Modern sheet metal technology includes: tungsten wire switching power supply winding, turning on light cutting, heavy processing, metal bonding, alloy drawing, plasma cutting, fine welding, roll forming, metal sheet bending forming, die forging, water spraying cutting, fine welding, etc.

The surface treatment of sheet metal parts is also a key link in sheet metal processing, because it can prevent parts from rusting and decorate the appearance of products. The effect of surface pre-treatment of sheet metal parts is mainly to remove oil, oxide scale, rust, etc. after surface treatment, the main solutions are spraying (baking) paint, spraying plastic and plating anti-corrosion coating.

Source: mini warehouse materials http://www.fcxjm.com

-

09-12

Commercial use and furniture use of mini warehouse

Commercial use mini warehouse deposit office store documents, goods, office Furniture and sundries, exhibition boards, task items, etc. are provided to meet the market demand for delivery of goods for customers, as well as address for business registration. They are more suitable for abnormal small and medium-sized enterprises and online business users to deposit goods. The mini warehouse can provide a warm and wide lobby. Customers can count goods in a wide space for home decoration or moving,

-

09-12

Design concept of mini warehouse

Mini warehouse is popular among warehouse types. Because we often have some idle, expired items in our home days. What kind of storehouse is the storage, such as books, childhood toys, etc. Most of them can be discarded, but some have the meaning of remembrance, which is the witness of your growth in a certain period, the planning of storage mini warehouse, or the reusable items, because you need to find a local storage place. The customers served by lazy warehouse are mainly to solve the storag

-

09-12

How to pay attention to fire and electricity prevention of mini warehouse in autumn and winter

Now has entered the autumn and winter season, wind high dry, a little careless on the simple cause of fire, fire for the mini warehouse is particularly important. The mini warehouse is a place where materials are concentrated. Once a fire occurs, the economic loss and social impact are huge, and the consequences are serious. Therefore, it is of great significance to do a good job in the fire control work of mini warehouse, ensure the safety of stored goods, and reduce fire hazards. The managemen

-

09-12

Two production processes of mini warehouse materials

Assembly process of mini warehouse materials: after spraying, the assembly process is started. Before assembly, the protective sticker used in the original spraying shall be removed to ensure that no paint or powder is sprayed into the internal thread hole of the parts. During the whole process, gloves shall be worn to avoid dust on the workpiece, and some workpieces shall be blown clean with air gun. Packaging of materials in mini warehouse: after assembly, the packaging process is started. Aft